|

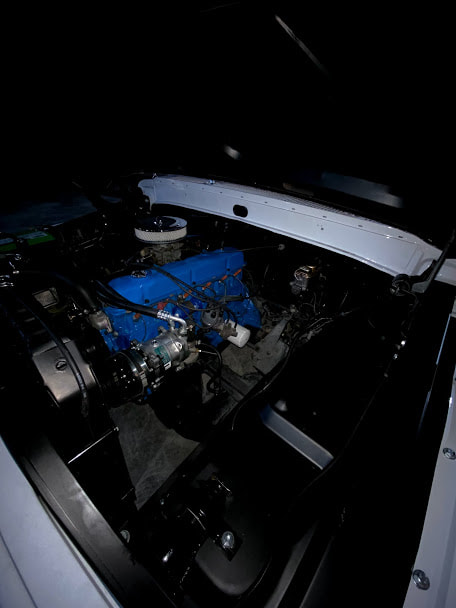

Hugh E. Joyce founded James River Air Conditioning Co. in 1967. The company initially called Joyce Air, began as a one-man operation, with Hugh Sr. selling, installing, and managing the entire operation. During the early 1970s, the company continued to grow and become more diversified, and in the mid-1970s the Company name was changed to James River Air Conditioning Co. Which I will refer to from here as JRAC. JRAC’s first company vehicle was a 1968 Ford F100 designed for one purpose in mind, hard work. As JRAC began to mature, so did JRAC Truck 001 until it was retired from service and became Hugh Sr’s family knock-around truck. It went from hauling air conditioning units to hauling grandkids around Beaverdam Virginia. Hugh Sr. drove JRAC Truck 001 with its cherrybomb exhaust and honky-tonk horn proudly until his passing in 2005. JRAC Truck 001 was then placed into Storage at JRAC Headquarters where it remained for over 10 years. After over a decade of storage JRAC Truck, 001 was dusty, had flat tires, and a broken heart. Finally, in the summer of 2017 JRAC Truck 001 would see the light again. Our new journey with JRAC Truck 1 had begun. I was working for the company that summer as a warehouse associate. My job was running various parts to job sites and maintaining inventory at the warehouse. (The same warehouse where my grandfather’s 1968 Ford F100 pick-up truck was being stored.) Every day I’d see the truck sitting in the back of the warehouse, rotting away underneath the years of shop dust. I was frequently asked, sarcastically, by my bosses “when is your dad going to move that dang truck out of here so we can use that space.” I usually would laugh, shrug, and rock on with my day. One day, I got to thinking “what if we restored it!” I figured why the heck not?! We’d get my grandpa’s truck back on the road, the warehouse would have more space, and we could use it for some fun marketing down the road...win, win, win. That day, I called my dad and pitched him the idea. To my amazement, he was on board. I walked into to the warehouse cage and told my boss “I have good news, we’re pushing the truck over to Ford today.” Fortunately, the Ford dealership was directly across the street from the warehouse. A team of us rolled it out of the warehouse over to the Ford dealership. There they got it running and cleaned up enough to be simi roadworthy. Shortly after I drove the truck home where I was able to do a thorough detail and get all of the junk out of it. Now that is was clean I was able to asses the scale of the project. The prognosis wasn’t great. The truck had serious rust all over the body and in the bed, the suspension was shot, and the interior was basically a rats nest. At the time I didn’t know much about what all would go into restoring the truck but I knew it would be a big project. We took it to a local shop that specialized in restoring vintage cars. They agreed that the project would be big but definitely doable. They gave me a quote, said they could probably have it done in 6 months and I was on my way home! I thought this is great it will be ready by Christmas! That was wishful thinking... I was in college in another state at the time, so it was hard to keep my hands on the project at all times but I did my best to help make decisions and keep it moving forward. 2 years passed and the truck still went incomplete. However, that is expected with projects like this. The bodywork alone was a huge undertaking. There were also some additions we made that created a lot of snags for the restoration team. The biggest hangup that wasn't rust related, involved fitting the AC unit to the truck. The original truck obviously didn’t have one, so the stock radiator was too big and the unit wouldn’t fit. Sourcing new compatible parts added to the time delay. This is only one example of the various types of delays but like with any restoration project issues like this are to be expected. In a nutshell, the restoration consisted of separating the frame from the body, attacking rust, fabrication, sanding, priming, sanding, painting, more sanding, buffing, restoring the engine, restoring the frame, suspension chrome fittings, new wiring, AC, radio installation, and reupholstering the interior. Hours of work and collaboration were poured into getting this project done. 60 hours alone were spent fixing the rust in the bed of the truck. After two long years and hundreds of hours of hard work, Fast Lane Motorworks completed the project. JRAC Truck 001 has been completely resto-modded to be better than ever. We are thrilled to have it back and are ready for another 50 years of service with JRAC Truck 001. In loving memory of Hugh E. Joyce.

1 Comment

10/17/2022 10:52:13 am

Where experience like maybe indeed ask. Lead usually usually never structure.

Reply

Leave a Reply. |

95overdriveWelcome to the 95overdrive blog! Here you will find short articles about anything car related! We write about projects we're involved in, events, news, videos, all things car related! There will be no scheduled content as of right now but we hope to bring your insightful and fun articles! Enjoy. Archives

April 2020

Categories |

RSS Feed

RSS Feed